Capabilities

We Offer

- Customized Machine Engineering and Design Services: Our company specializes in the creation of tailored machine solutions designed to meet the unique and specific requirements of our clients.

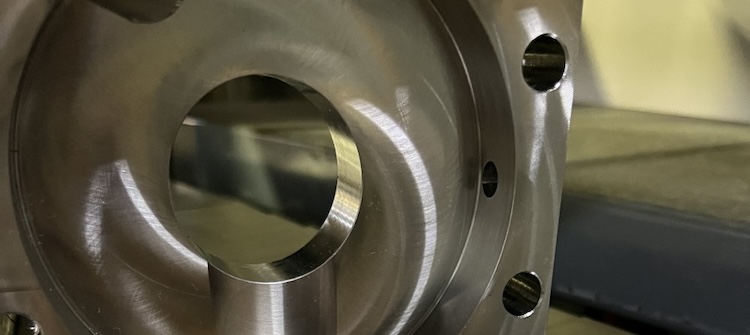

- In-House Machining Expertise: Our comprehensive in-house machining capabilities cover a wide spectrum, from small to large sizes and short to long production runs. We work with a diverse range of materials available in today’s market.

- Complete Assembly Services: Beyond machining, we provide a full spectrum of services, including surface finishes, welding, electrical panel assembly, hydraulic and pneumatic system integration, as well as electrical and mechanical assembly. Our aim is to deliver turnkey solutions to meet your requirements.

- Technical Consultation: Leveraging our extensive experience in building new machines, sub- assemblies, and refurbishing equipment, we offer expert technical consultation to support your decision-making process.

- Spare Parts and Tooling: For our machine-build customers, we offer a reliable source of spare parts and essential tooling. Additionally, we maintain an inventory of critical spare parts to ensure seamless ongoing support.

In essence, our company excels in custom machine engineering and manufacturing, delivering a comprehensive range of services encompassing design, machining, assembly, and technical guidance.

Our certifications underscore our unwavering commitment to delivering top-notch solutions that meet the highest quality standards, benefiting both our business and the success of our clients.

MANUFACTURING CAPABILITIES

- Quality machine services since 1945

- ISO9001:2015

- U/L Registered (C.E. compliant)

- Contracted services from concept to finished product

- Contracted engineering drawing services

- Mechanical, Electrical, Hydraulic, Pneumatic, Robotic

- Electrical Panels & assembly – U/L & C.E. Certified

- Large 10,000 square foot assembly bay

- Ample loading dock and facilities

- Saw-cutting all sizes and types of materials

- CNC & Conventional turning to 40” diameter

- Conventional Vertical turning to 50” diameter

- CNC & Conventional milling to 60”wide x 80”lg x 78”high

- Drilling all diameters to 80” radial arm

- Conventional Boring to 50”wide x 50”long x 50”high

- Other sizes available from our many business partners

- Surface grinding to 16” wide x 32” long x 16”high

- Blanchard grinding to 46”diameter x 36”high

- MIG

- TIG

- ARC

- Weldments of all types and sizes

- Sandblasting

- Painting – large capacity spray booth

- Plating of all types

- Specialty finishes

CAPABILITIES

ENGINEERING CONSULTING

The ability of your business to reduce costs is directly related to the efficient operation of your production equipment. We realize that the procedures surrounding this process must be constantly updated, oftentimes with the objectives of accelerated project and production schedules requiring process efficiencies.

Butler Tool, Inc. can work with you to analyze your requirements and production goals, examining any difficulties and helping you to discover opportunities for streamlining your equipment processes. This streamlining process establishes benchmarks for your activities.

The benefits of outsourcing include providing greater budget control, enabling organizations to pay only for services, processes, and parts they need, when they need them. In addition, outsourcing allows the business to focus on their core competency, and gain access to more specific knowledge, services, and experience. The end result is increased profits.

At Butler Tool, Inc., this is at the heart of what we do. Going beyond our engineering, precision machining, and assembly services, we provide customized inventory management to remove the expense and burden of these activities. The resulting efficiencies that we bring to the table in outsourcing enable our customers to focus their resources and attention toward improving their business.

CAPABILITIES

OUTSOURCING

CAPABILITIES

STRATEGIC SOURCING

CAPABILITIES

PRIMARY MANUFACTURER

Our Stocking & Distribution team understands the value of time and space. Butler Tool, Inc has an unmatched ability to not only serve our customers’ design and manufacturing needs but manage product Stocking and Distribution. Storing your product within our facility not only saves you valuable space but provides a peace of mind that you can always have the items you need, where you want them, at the right time. We’re always ready to serve our customers with around the clock monitoring of distribution requests, keeping your projects on track for a successful outcome.

CAPABILITIES